Serving clients in the roll form industry, Forever Machinery drives the innovation of roll form process design for various open and closed profile. Engage with our market-savvy consulting engineers to discuss your profile forming needs.

Profile Forming Lines

Beyond round pipes and hollow sections, FRV Tube Mill supplies profile forming lines to produce a variety of open and closed-section roll-formed profiles. These lines are targeted at manufacturers of cold-formed sections such as C-channels, U-channels, angles, Z-profiles, door frames, roofing sections, as well as specialty closed profiles (welded or non-welded). Serving clients across the broader roll forming industry, FRV prides itself on innovative roll form process design for these applications

Open Profile Forming Lines

These are roll forming machines that create profiles which remain open (no welded seam) – for example, purlins, channel sections, guardrails, etc. FRV’s engineering team works with customers to customize the roll tooling for the specific cross-section needed. The lines typically consist of a decoiler, leveling equipment, a roll forming mill with multiple stands that progressively shape the strip into the target profile, and cutoff presses or flying saws to cut the profile to length.

Closed Profile Section Forming Lines

These refer to roll forming lines that produce closed shapes, which generally means there is some form of joining (often welding) to close the profile. This could include lock-seam profiles, welded tubes of non-round shape, or other tubular profiles that are not standard pipes. FRV’s closed profile lines likely overlap with their ERW tube mills for certain shapes (e.g. oval or D-shaped tubes, etc.), but may also cover unique products like welded structural sections, automotive structural profiles, or enclosure shapes. Our company’s ability to innovate in roll form process design means they can accommodate custom requirements – for instance, integrating welding stations for longitudinal seam welds or punching stations for perforated profiles if needed.

Our Focus

FRV’s focus in profile forming is on providing tailored solutions. Unlike off-the-shelf equipment, these lines are often custom-designed to the client’s product. We aim to drive innovation for various profiles and assure customers that they can meet their needs with the right engineering. This customer-centric, solution-driven positioning is a key service point.

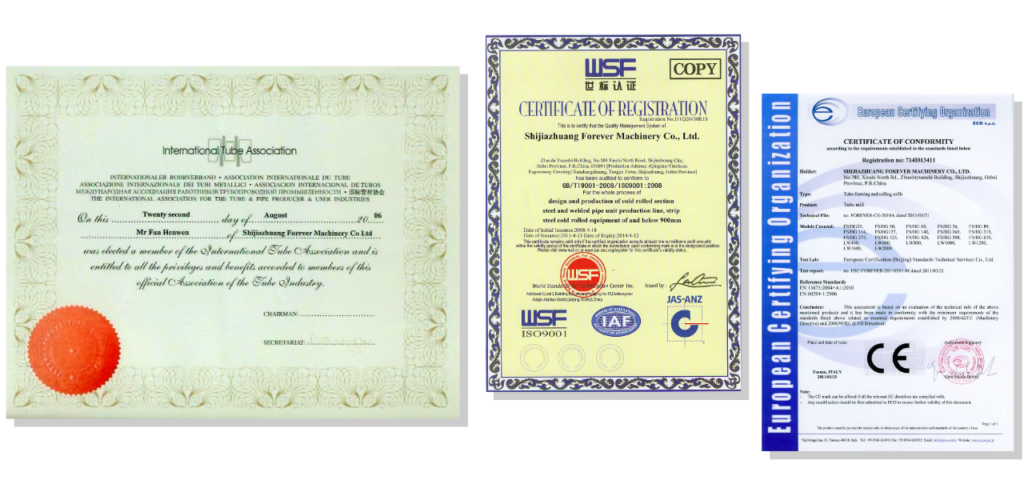

Accreditations

We pride our selves in our 30 years’ experience in roll form engineering and ERW tube mill design. We look after our customers every step of the way throughout the entire manufacturing lifecyle and offer our insights & services on optimizing their roll form equipment.