The square or rectangular shaping is formed out before the tube welding, with important advantages in terms of power and material cost reduction.

The square or rectangular shaping is formed out before the tube welding, with important advantages in terms of power and material cost reduction.

As part of our comprehensive offerings, FRV Tube Mill provides coil processing equipment including slitting lines and cut-to-length lines. These lines serve as essential auxiliary processes for tube and roll-forming manufacturers, enabling them to prepare raw material coils to the exact dimensions needed for production. FRV’s capability extends across light to heavy gauge coil processing – “ranging the spectrum of slitting lines, cut-to-length lines, painting & coating lines, and stamping lines” This means we can supply everything from small precision slitting machines for thin coil up to heavy-duty lines that can handle wide, thick steel coils.

A slitting line uncoils a master steel coil and slices it into multiple narrower strips (slit coils) of desired widths. Tube mills typically require pre-slit strips as input (for example, a 1250mm wide coil might be slit into several strips of a specific width to form particular tube diameters). FRV offers slitting lines such as the models indicated (e.g. 2×1300, 4×1600, 8×1600 lines, etc., where the numbers denote thickness × width capacity in mm). Features of modern slitting lines include precision rotary shears, loop bridges or tension stands to maintain proper strip tension, and recoilers to wind the slit strips. FRV’s heavy-duty slitting lines are built to cut high-strength steel without burrs, while high-speed slitting lines focus on throughput for high volume operations.

A CTL line uncoils and flattens steel coil and then cuts it into flat sheets or plates of specified length. FRV’s offerings (e.g. Heavy Duty CTL and High Speed CTL lines) likely cater to different needs – heavy-duty lines can handle thicker material (perhaps for plate and structural blanks) albeit at slower speed, whereas high-speed lines handle thinner gauges at rapid cycling to produce sheets for automotive or appliance industries. Key components include an uncoiler, straightener leveler (to eliminate coil curl), a feeder and shear (or hydraulic cut press), and stacking/packing system for the cut sheets. By providing CTL lines, FRV enables its customers to produce flat sheet products or blanks in-house, or simply to prepare material for downstream processes.

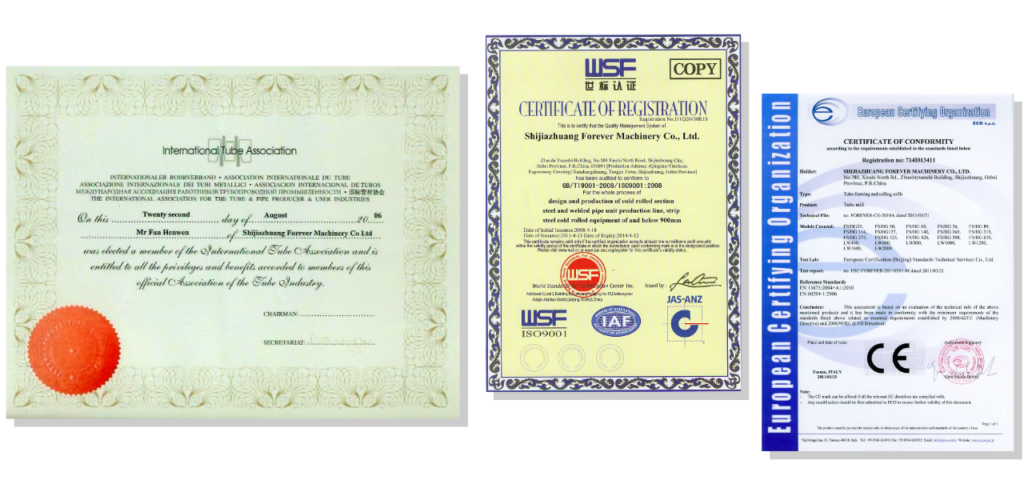

We pride our selves in our 30 years’ experience in roll form engineering and ERW tube mill design. We look after our customers every step of the way throughout the entire manufacturing lifecyle and offer our insights & services on optimizing their roll form equipment.