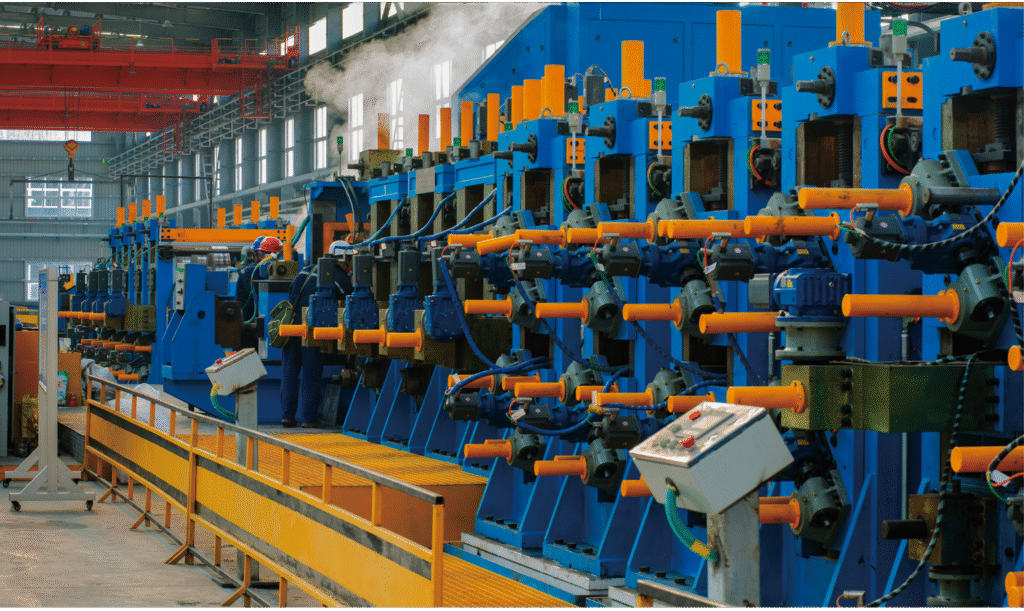

The square or rectangular shaping is formed out before the tube welding, with important advantages in terms of power and material cost reduction.

Direct Forming Lines for Hollow Sections

Direct forming lines represent one of FRV’s top technological services, allowing customers to produce square and rectangular hollow section tubes directly from flat strip without first creating a round tube. FRV (Forever Machinery) has “spearheaded the development and implementation of direct forming technology in the tube & pipe industry”. In a conventional ERW mill, making square/rectangular tubes often requires forming a round tube and then reshaping it in a sizing section – a process that entails extra steps and roll changes. Direct Forming Technology (DFT) eliminates this by forming the strip directly into the final square or rectangular shape prior to welding.

Advantages of Direct Forming Lines

Some common benefits are no round pre-form needed (saving the step and rolls for round forming), less deformation strain on the edges (often yielding better section corner quality), and the ability to produce custom hollow profiles that might be challenging via conventional methods. Direct forming also tends to reduce the strip width required for a given hollow size, translating to material savings over the long run. This technology is especially valuable for large hollow sections (e.g. square tubes for structural use) where the material and energy savings are magnified.

Frequently Asked Questions

Direct Forming Technology (DFT) refers to the process of forming square or rectangular tubes directly from flat strip without first making a round tube. In traditional ERW tube production, even if the final product is a square/rectangular hollow section, the mill first forms a round tube, welds it, and then reshapes it through a sizing section into a square. DFT skips the intermediate round step: the rolls gradually shape the strip into a square or rectangular form before welding, and then the HF welder closes the seam at the corner of the section. This technology, which FRV has pioneered in its direct forming lines, offers important advantages in terms of power and material cost reduction

Because you’re not over-working the metal by rounding and then squaring it, there’s less strain and the forming is more efficient. Additionally, DFT allows quick size changeovers when paired with adjustable tooling – operators can change the section dimensions (say from a 100×100 mm square to a 150×150 mm square) with less downtime, especially on advanced lines with motorized roll adjustmentsfrvtubemill.com.au. It also means a factory can produce many different hollow section sizes on one line without needing a separate dedicated mill for each size.

From a product standpoint, direct forming can improve the quality of the hollow sections – the edges of the strip become the corners of the tube, and with proper process control, you can achieve uniform wall thickness and right-angle corners. This method is well-suited for structural tubes and any application where different sizes of rectangular/square tubing are in demand.

Direct forming technology is an innovative tube mill process that makes production of square/rectangular steel tubes more efficient and flexible. FRV’s direct forming lines are an example, bringing this technology to customers who need high productivity and a wide size range for hollow sections. If you see terms like “LW600×600 direct forming line”, that denotes a line capable of making up to 600×600 mm sections with DFT. For a manufacturer, adopting direct forming technology can lead to lower conversion costs (energy & scrap savings) and a more agile production capability.

Accreditations

We pride our selves in our 30 years’ experience in roll form engineering and ERW tube mill design. We look after our customers every step of the way throughout the entire manufacturing lifecyle and offer our insights & services on optimizing their roll form equipment.