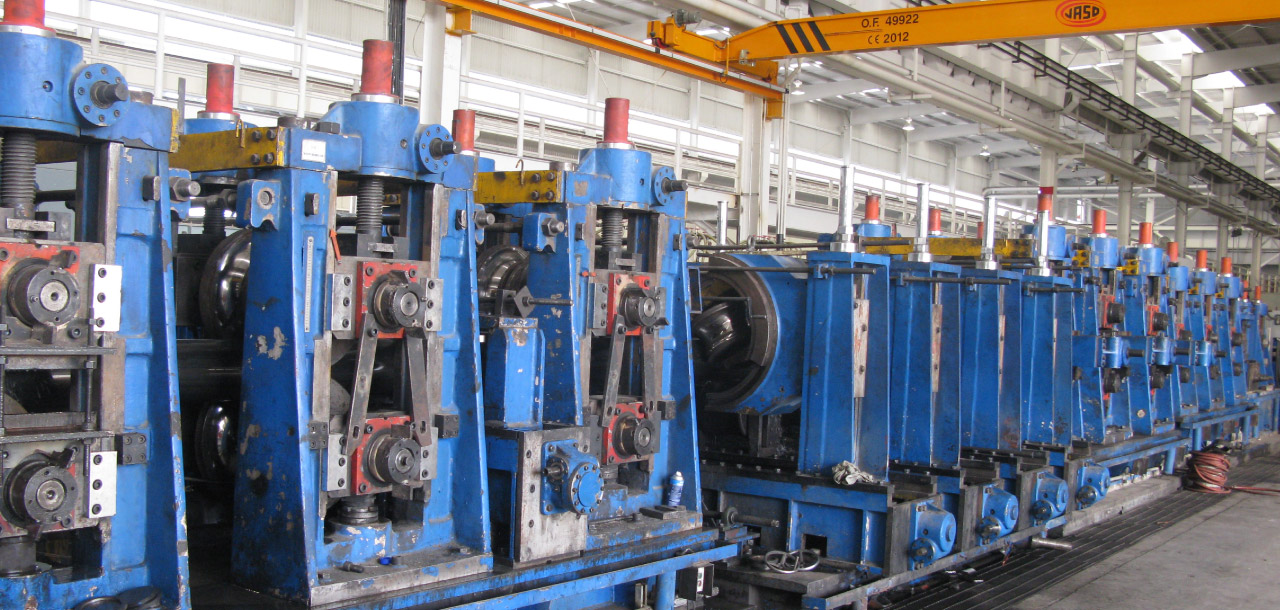

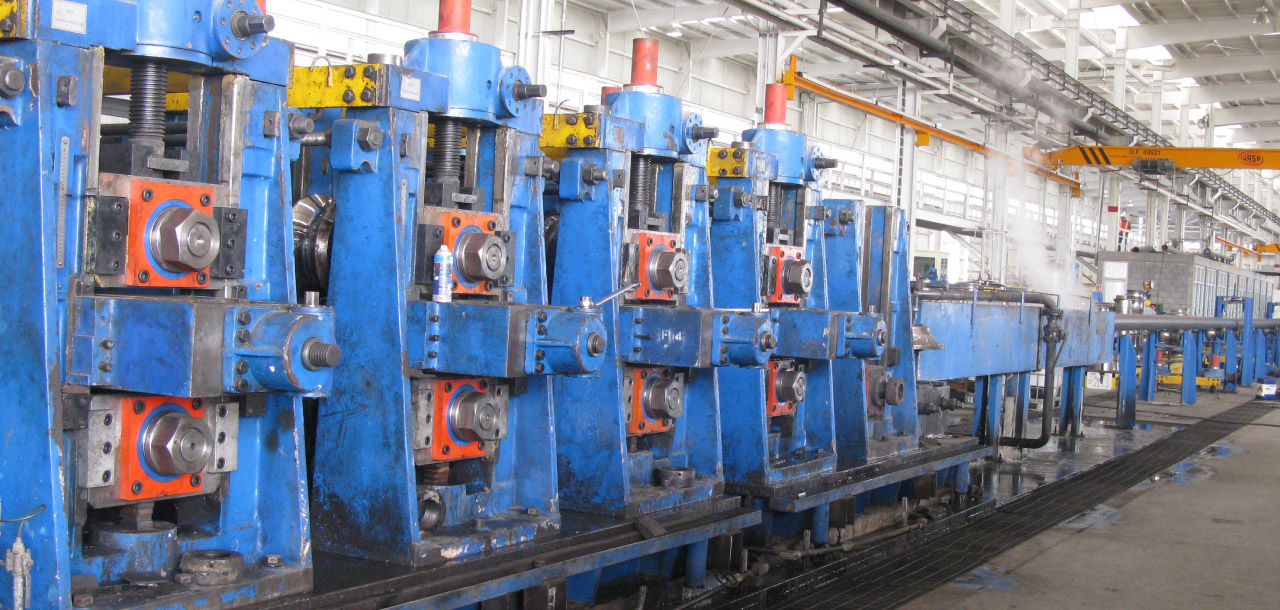

325 Tube Mill

Function: This pipe is used especially for Petroleum, Natural gas, City gas, Pipe network, Chemical industry, Electricity, Steel truss, Water and Gas pipeline; it is widely used for a variety of pressure pipelines

Process flow: Coil loading—Uncoiling—Pinching & Leveling—End Shearing‐Strip joining—Horizontal spiral strip accumulator—Forming‐HF Welding– O.D bead cutter–SEAM ANNEALER —Cooling—Sizing & Turks head‐Measuring roll—Flying cut off machine—Run out conveyor_ End facing & chamfering_ Hydrostatic Test- Ultrasonic Testers—Packing