Precision Tube Mill

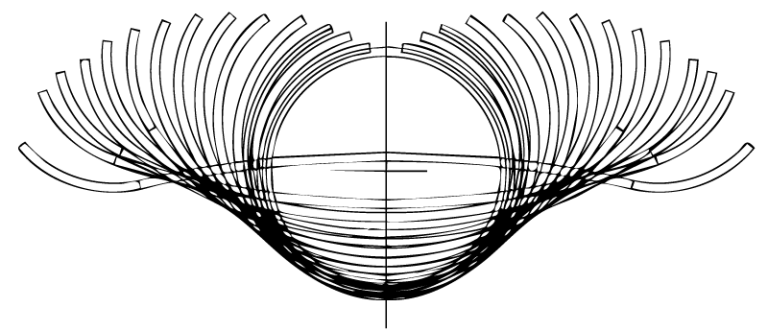

Producing tubes with fine tolerance and surface roughness

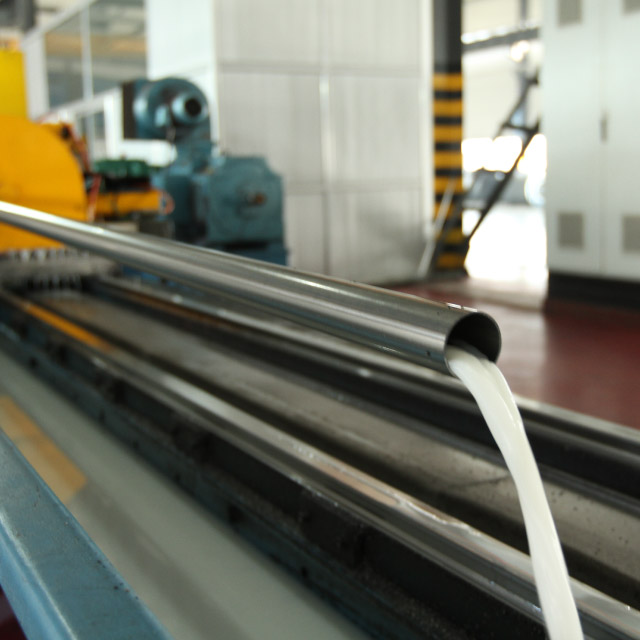

Over the years, Forever Machinery has designed and manufactured dozens of precision tube mills for automobile and power transmission industrial, which were all meticulously engineered with carefully selected components.

- Size ranging from 12.7 OD to 101.6 OD

- Capable of achieving a tolerance of 0.025mm

- Robust and impeccable flexibility