Flexible Forming Line

Flexible Forming Excellent (FFX) in roll forming technology is an advanced technique that enhances the capabilities of traditional roll forming. It refers to the ability to create complex, customized profiles with greater precision and flexibility by utilizing advanced tooling, automation, and control systems. This method allows for a broader range of material thicknesses, shapes, and profiles compared to conventional roll forming.

FFX involves a combination of flexible tooling and precise control mechanisms that allow manufacturers to adapt the forming process to different material properties and design specifications. It’s particularly useful when producing parts with intricate geometries, non-standard profiles, or when rapid adjustments are needed in the production line without significant downtime.

Advantages of FFX over Conventional Forming:

Enhanced Design Flexibility:

FFX allows for more complex and varied shapes to be formed compared to conventional roll forming, which is typically limited to simpler, more uniform profiles.

Reduced Tooling Costs:

Traditional roll forming often requires significant investment in dedicated tooling for each part design. FFX uses more flexible tooling systems that can be adjusted or reconfigured for different profiles, thus lowering tooling costs and setup times.

Shorter Changeover Time and Machine Downtime:

Unlike conventional roll forming, which requires manual retooling for different part designs, FFX systems use modular and adjustable tooling. The ability to change or reconfigure these tools with minimal effort means that you can switch between different profiles or material types faster. In traditional systems, changing tools can take hours, but with FFX, the changeover can often be done in minutes, cutting down the time spent on retooling.

Improved Material Utilization:

FFX can handle a wider variety of materials and thicknesses, leading to less waste and more efficient use of raw materials. This is especially valuable for products that need to be made from specific or specialized materials.

Higher Precision and Quality:

The precise control systems used in FFX can result in better dimensional accuracy and surface finishes, leading to higher-quality final products.

Reduced Need for Post-Processing:

FFX enables the creation of profiles that may otherwise require secondary processes (like cutting, bending, or welding) in conventional methods. This reduces overall processing time and cost.

Customization and Small-Batch Production:

With FFX, it’s easier to run low-volume, customized orders without significant additional costs for retooling or setup. This is ideal for industries requiring bespoke or small-batch production.

Flexibility in Adjusting to Design Changes:

If the design needs to be altered during the production run, FFX systems can be adapted quickly, providing a faster response to design changes without significant downtime.

Improved Material Utilization:

FFX can handle a wider variety of materials and thicknesses, leading to less waste and more efficient use of raw materials. This is especially valuable for products that need to be made from specific or specialized materials.

Improved Sustainability:

FFX systems often integrate advanced automation and real-time adjustments to the process, improving consistency and reducing the chance for human error.

In summary, FFX in roll forming technology offers superior flexibility, efficiency, and adaptability over conventional methods, making it particularly well-suited for complex, customized, or small-batch production runs.

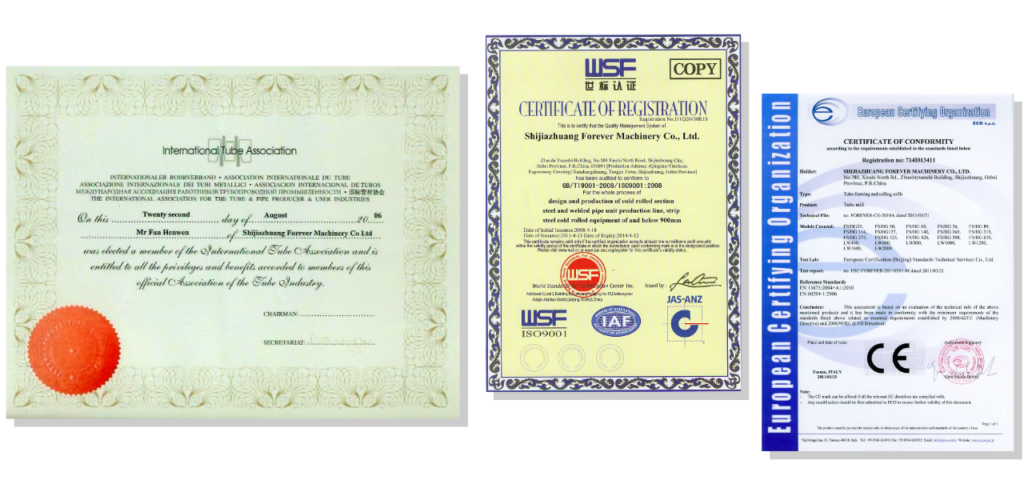

Accreditations

We pride our selves in our 30 years’ experience in roll form engineering and ERW tube mill design. We look after our customers every step of the way throughout the entire manufacturing lifecyle and offer our insights & services on optimizing their roll form equipment.